DESIGN

Our hydraulic engineers design accumulator systems and the corresponding hydraulic peripherals based on to the specifications of our customers.

PRODUCT SELECTION

Our specialists will help you choose the correct accumulator size, the correct system configuration and the right products. It all depends on your specifications or the structural requirements of your hydraulic system.

CONVERSION - EXTENSION - EXCHANGE

Our teams of engineers, project managers and service technicians implement conversion or revision projects, which are coordinated with the customer, in accordance with the agreed scope and deadline.

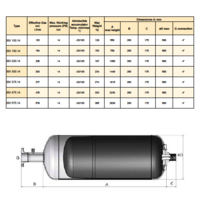

During this process, old accumulators of any brand (Bosch Rexroth, Hydac, etc.) – see image above – are replaced with modern versions of the Parker Olaer brand – see image below.

TESTING

Our colleagues, who are specially trained to meet the specific requirements of low-pressure and high-pressure hydraulic accumulators, take the utmost care when testing the pressure equipment.

Dismantling, testing and replacement of components that are no longer operational, as well as assembly and pre-filling, all form part of our daily work.

Since 1 June 2015, operators of hydraulic accumulators have been subject to stricter obligations regarding measure implementation. As we are experts in dealing with hydraulic accumulators, you have found a trustworthy partner in us. We subject your hydraulic accumulators to a precise test in accordance with the German Ordinance on Industrial Safety (Betriebssicherheitsverordnung), the Pressure Equipment Directive (Druckgeräterichtlinie) and the Ordinance on Business Premises (Betriebsstättenverordnung) - and we do this on a regular basis and on schedule. We also undertake the responsibility for reporting your hydraulic accumulators to the Authorised Inspection Body (Zugelassene Überwachungsstelle - ZÜS)/Federal State Plant Register (Anlagenkataster der Länder - ANKA). This puts you in a safe position, as you fulfil your reporting obligation and always check and operate your hydraulic accumulators safely.

Everything from a single source

With us, you receive the service from a single source: We are your single point of contact and take care of the testing, reporting and inspection, as well as maintenance and documentation, and we always work in accordance with the guidelines during these processes. Take advantage of our hydraulic accumulator services. Our expert staff will be pleased to help you and will advise you in detail on the subject of hydraulic accumulators.

COMMISSIONING

Direct delivery of the ordered and preconfigured components as well as adjusted components to the specific site of operation of the accumulator.

Our service technicians will commission all delivered accumulators.

DOCUMENTATION - ANKA & ZÜS

Pressure equipment and hydraulic accumulators are systems that must be inspected and for which the respective operator is obliged to register in the ANKA (Federal State Plant Register) via a ZÜS (Authorised Inspection Body).

We are happy to support you here as well.

CONTROL, MAINTENANCE & PREVENTIVE REPAIR

Our experience shows that preventive checking and maintenance of components or system parts is better than problem solving in the event of an accident.

That is why we regularly check hydraulic accumulators that we have installed and recommend maintenance to our customers if necessary. This avoids machine downtimes and loss of production from the outset.

We provide you with an all-round worry-free package with regard to the service and repair of hydraulic accumulators. Our services include the replacement and repair of hydraulic accumulators, as well as drawing up the associated documentation. You can rely on us completely. We will support you in risk assessment and carry out any necessary maintenance work on your hydraulic accumulators. We also take care of organising the maintenance and testing intervals, as well as the replacement of pressure accumulator components that can no longer be repaired. In addition, we carry out accumulator tests and other necessary repairs. Filling hydraulic accumulators is no problem either. While doing so, we always draw up test reports and comprehensive documentation so that we can subsequently register your hydraulic accumulators at ZÜS/ANKA. We also offer you ongoing support with regard to your hydraulic systems and will be happy to advise you on optimisation options.

We offer you all services from a single source: We are your point of contact and will undertake the coordination of all necessary resources to ensure that your wishes are fulfilled to your complete satisfaction. Our competent team will advise you continuously and point out optimisation options. In addition, we will coordinate all necessary measures and deadlines with the ZÜS. We will undertake the inspection and documentation. Moreover, the installation of hydraulic accumulators and their accessories will be carried out by our specialist personnel. We use tracking codes (PTS labels) as identification measures here. We also fulfil all document management requirements and approve all test-relevant components. In addition, we offer ZÜS approval for complete systems and have spare parts and hydraulic accumulators ready for emergencies.