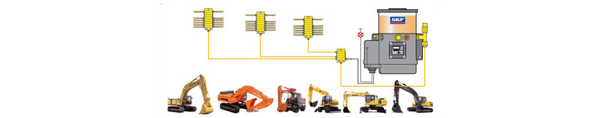

Lubrication systems and central lubrication plants ensure ideal lubrication quantities at the right time in the right place. They are used for lubrication of individual machines and complete plants and allow clean and efficient lubrication distribution to all connected lubricating points. Several machines and plants can be supplied and monitored by a single system when using central lubrication.

As a contractual partner for SKF Lubrication, we are able to advise you on all questions concerning lubrication technology and help you solve your specific issues with regards to lubricants, spare parts and assemblies.

We help you design new systems, rescale and expand existing lubrication plants, carry out troubleshooting in pump assemblies and piston distribution, advise you regarding the selection of the right lubricant, maintain your devices and plants and take on functional responsibility over the life cycle of your plant.

lubrication systems & central lubrication plants

Wrong lubricant distribution can lead to friction and early wear and damage to components or even entire plants. Too much lubricant leads to waste, unnecessary contamination and can in extreme cases even put people, machines and environment at risk.

SKF offers a range of different automatic lubricators. Lubricators for individual lubricating points supply individual lubricating points at pre-defined time intervals. Gas-powered lubricators are a cost-efficient alternative and are suited for hazardous environment with limited space. Electro-mechanical lubricators can manage even greater distances with a pressure of up to 30 bar and therefore supply hard to reach lubricating points.

The Multipoint system can as central lubrication supply several lubricating points at the same time with the same grease type. The lubricant can be distributed to about 20 locations simultaneously using an electric pump.

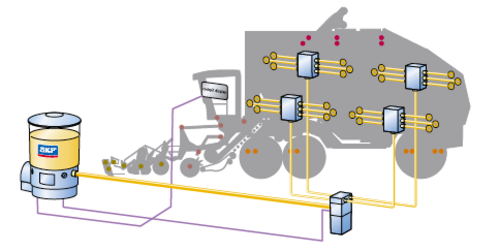

Single-line lubrication systems such as the MonoFlex system provide the lubricant to a distributor using a pump. The lubricant requirement can be adjusted here individually before the medium is supplied to the lubricating points.

Two-line lubrication systems have two main lines which can supply several distributors. This allows the supply to over 1000 lubricating points using just one pump assembly.

Multi-line lubrication systems convey the lubricant directly to the lubricating point. Every lubricating point has a single pump element and can be supplied individually. The MultiFlex system can supply up to 32 outlets with a system pressure of up to 4000 bar. It is suitable for smaller oil circulation lubrication systems as used e.g. in tool machinery.

For progressive lubrication systems, the lubricant is conveyed via a main line to a distributor and from there to the individual outlets. The system is designed for smaller to medium-sized machines and allows continuous supply of the lubricant during the entire pump duration.

Minimum quantity lubrication systems

Minimum quantity lubrication systems have the task to apply small quantities of lubrication between tool and workpiece. The minimum quantity lubrication can occur in two different ways. For internal lubrication, the aerosol of compressed air and lubricant is applied directly on the friction area between tool and workpiece. For external lubrication, the aerosol is applied by nozzles from the outside. Tool machines can be retrofitted if necessary with an external minimum quantity lubrication.

Special applications

SKF offers tailor-made lubrication systems for special requirements. Thanks to long-standing experience in lubrication technology, the company is in a position to offer a suitable, cost-efficient and effective lubrication system for any situation. Special systems are used e.g. in modern locomotives or wind power plants.

SKF also offers grease spraying plants for large, exposed gearbox plants as used in mining or steel production. The grease spraying plants ensure an even lubricating film on the surface of the pinion gears.

Dry lubrication systems for conveyor plants are used for apron conveyor chains and other conveyor belts. Small quantities of dry lubricant are applied in an exact dose to conveyor chains and guides using central lubrication. Spraying of water and soluble lubricants can be omitted which reduces the risk of product contamination significantly.

Cylinder lubrication systems for diesel engines are used for large crosshead two-stroke engines on container ships, oil and gas tankers and bulk cargo carriers. Great quantities of lubricants and hence operating costs can be saved when the right system is used.

Talk to us with regards to our products and service ranges for lubrication systems and central lubrication plants by well-known manufacturers such as SKF or products by Willy Vogel Zentralschmierungen.

We offer these products and services in 6 locations around Germany:

Brandenburg: Senftenberg, Frankfurt/ Oder

Berlin: Schöneiche, Genshagen

Saxony: Dresden, Leipzig