Central lubrication plants have become an essential part in many industrial and mobile hydraulic environments. Our engineers can advise you with regards to lubrication technology, oil circulation lubrication and greases; they can also assist you with the maintenance and procurement as well as design, adaptability, configuration and documentation of your existing plants.

Contact us any time either by getting in touch with one of our subsidiary in your area or by sending us an enquiry.

We supply products and offer services for the product ranges by the following companies: Vogel Schmiertechnik, Willy Vogel Schmiertechnik, Willi Vogel, SKF, SKF Lubrication, Willy Vogel Berlin, Cirval, Safematic, Vögele, Lincoln Zentralschmiersysteme.

Central lubrication

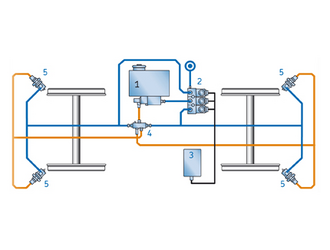

A central lubrication plant ensures continuous lubrication supply for various lubricating points, which are located within a technical plant.

Standard lubrication technology

Friction points were traditionally lubricated by manual local lubrication; during this process, the lubricants were applied with a grease gun on the individual lubricating points. This was not only time-consuming but also difficult to dose accurately. Too much lubricant is an unnecessary expense, contaminates the technical plants and does not only burden the friction point but potentially also the environment. On the other hand, if too little lubricant is applied, it may lead quickly to machine failures due to bearing damage.

Advantages of central lubrication

Centralising the lubrication technology allows lubrication to be applied in accurate doses and therefore protects lubricating points perfectly against wear by providing protective, consumption-optimised lubrication. Central lubrication plants also reduce the maintenance effort in comparison to individual lubrication methods, since it is only necessary to check the fill level of the lubricant tank.

Initially, however, the introduction of central lubrication technology will create additional costs for purchase and installation and will result in a more complex plant structure.

Manual and fully automatic central lubrication technology

Central lubrications can be carried out manually or fully automatic. Fully automatic central lubrication plants available today ensure operational plant safety and monitor lubricant supply quantities mostly using electronic and visual means. An automatic, central lubrication supply very reliably prevents a production stoppage due to plant downtime or due to lubricating point damage (which is the cause for one third of all bearing damages) caused by lack of lubrication.

Consumption and circulation lubrication

If the plant design allows it, central lubrication can be installed e.g. as (additionally cost-saving) oil circulation lubrication. In this process the lubricant - different to consumption lubrication - can be reused after being returned into the central tank and being processed.

Lubricants used

The central lubrications of technical plants require individually suitable lubricants, which are available in different aggregate states. Liquid lubricants include cooling lubricants and lubrication oil. Furthermore, greases, solid lubricants such as graphite and gaseous lubricants are used.

Application scenarios

Central oil circulation lubrication is e.g. used in combustion engines. The lubrication oil for oil lubrication is pumped from the oil tank (lubrication tank) through an oil filter (processing station) using an oil pump. It is then supplied to the different lubricating points via the channels located in the engine and is then returned back to the tank.

Further areas of use of central lubrication plants are e.g. tool and textile machines, conveyor belts and industrial plants such as sawmills and rolling mills. Central oil lubrications are used e.g. in commercial vehicles such as construction machines, combine harvesters and tractors.

Step-by-step integration of central lubrication technology

Conversion to an automatic central lubrication plant can be done in stages. It is possible to initially summarise lubricating points to (still manually supplied) partially centralised lubricating points, which are supplied in a second step from a single central lubricating point. In an additional development step, it is possible to initially automate the control and then also implement the monitoring of the central lubrication plant.